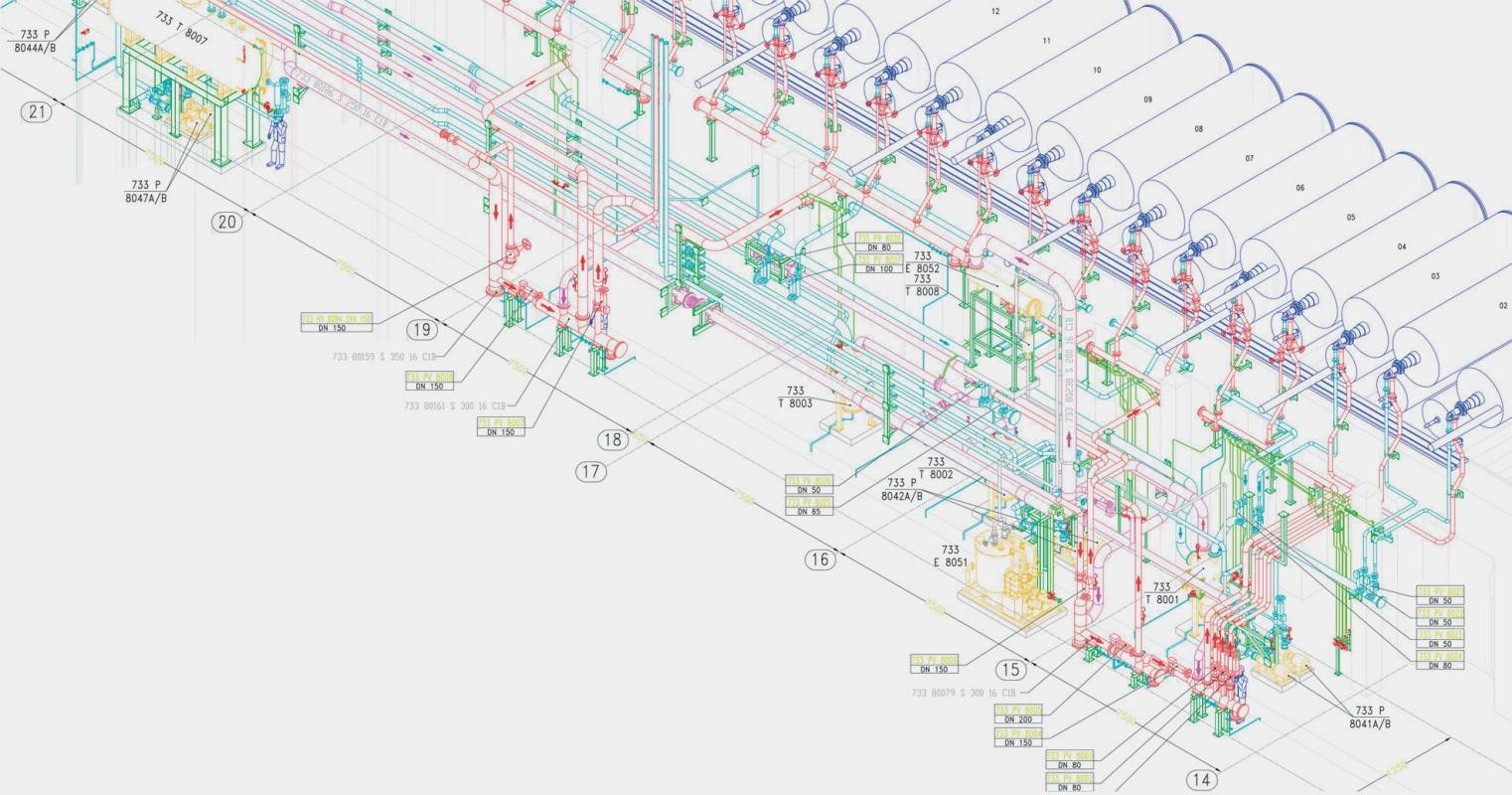

Steam & Condensate systems

Modern and optimized Steam and Condensate systems

Our steam and condensate systems are designed clearly and rationally. According to us, a well-designed system must be able to maintain high performance and low consumption over the entire operating range of the machine.

The dryer section of the paper machine consumes large amounts of energy.

The steam and condensate system controls the steam pressure for an optimum drying, provide stable control over the entire operating range and efficiently remove condensate from inside the dryers.

The accurate assessment of the dryer section by Lario Energy engineers and professionals can detect opportunities for the energy efficiency improvement, runnability, and productivity.

A flexible and simple system

Lario Energy supplies steam and condensate systems are adapted to the required drying rate of the paper machine and product grade.

Lario Energy’s steam and condensate system can deliver an increase up to 20% of the drying capacity.

At the same time, the energy saving obtained with a lower steam consumption can reach 15%.

In addition, the rational design of the system, the careful sizing, and the choice of top-quality components make it possible to minimize maintenance, breakdowns, and downtime.